Oh, geez. How have we made it this far without ever discussing EV batteries? Well, we’re finally about to. And frankly, this probably should’ve been the first thing I covered. So take your seat and turn up that screen brightness. Battery packs, often called “traction batteries” in full EVs, are the powerhouse supplying juice to the growing fleets of electrified cars rolling out of automotive plants by the thousands.

It’s the focal point of curiosity and innovation in advancing the electric car species but also a subject of great controversy regarding environmentalism and sustainability. We can’t mention electric cars without bringing up their batteries. But now it’s time to get a grip on how they work, what goes into them, and what sets the different castes of batteries apart.

Let’s begin with a simple science lesson. Or, well, as simple as we can make it!

How does a battery usually work?

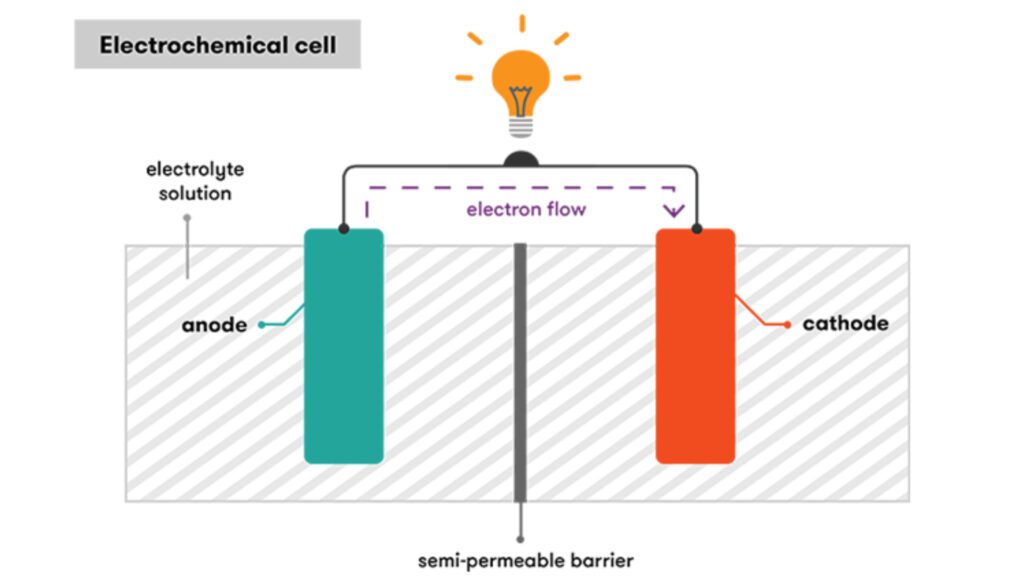

In the most basic explanation possible, batteries are composed of metallic electrodes – a positive-side cathode and a negative-side anode – and an electrolyte separating them. The electrolyte is a medium through which ions flow between the cathode and anode carrying charged particles. The chemicals between the electrodes equilibrate in the electrolyte as ions flow, turning the stored chemical energy into electrical energy. When wired into a circuit, whether a car or a simple home appliance, this flow routes electricity through the wiring to power whatever external device is in use. The negative anode spews electrons through oxidation to send power wherever it needs to go, while the positive cathode accepts electrons to complete the circuit.

For a more convoluted explanation, please pester your local high school chemistry teacher, college physics professor, or the neighbor’s electrician. Or better yet, the Massachusetts Institute of Technology. Something tells me those people probably know a thing or two.

What makes up an EV battery?

The core principles of a battery remain. There are cathodes, anodes, and electrolytes to rule them all. However, in the case of an electrified car, the main battery delivers its juice in exponentially higher doses, encasing the ingredients in cells that join together to form a complete battery pack. Take your standard 12-volt accessory battery and multiply that by a couple dozen folds. Hell, maybe even more.

Although we’re used to rating simple household AAs or automotive accessory batteries in voltage or amps, we treat these goliath-sized battery packs a little differently. Traction batteries, like fuel tanks, are typically rated for capacity, usually in kilowatt-hours. And while we’re on this, it’s important to note there’s a difference between the total gross capacity of a battery, which is the total energy the battery contains and the figure most automakers love to advertise, and actual usable capacity, which is how much energy the car can actually draw on for power.

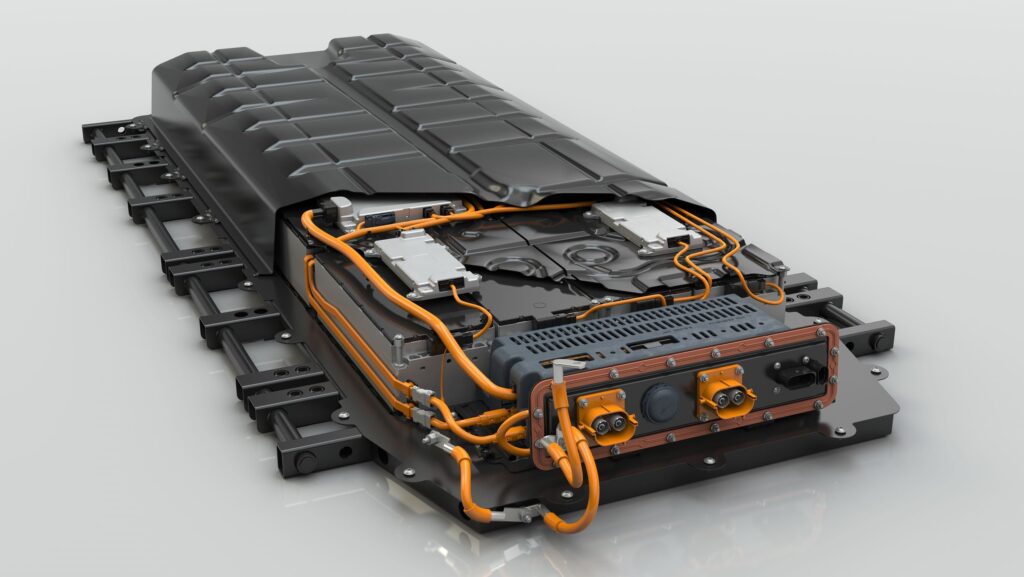

Most present-day EVs operate in the ballpark of 400 or 800-volt architectures, with stragglers falling a tad lower or even shooting higher. Such immense power demands battery packs that can handle the load and keep on delivering for hundreds of miles and hours of driving. Seems intimidating having all the power beneath your posterior, but thankfully, that’s what battery management systems are for, which keep a watchful eye on parameters such as voltage, overall battery health, and, perhaps most importantly, thermal management.

While all traction batteries are constructed similarly, automakers usually arrange them in any of the following ways.

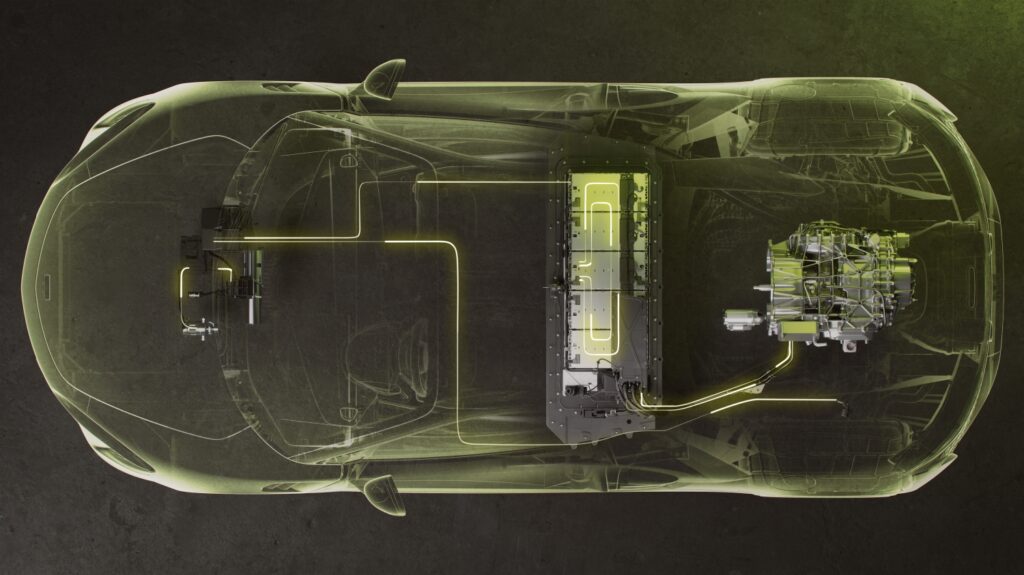

Skateboard battery, a vision of a customizable future.

Perhaps the most interesting of them all, and the one proving increasingly popular, are skateboard battery packs, which lay their many cells in a flat plane, comprising a sort of floorboard for an EV. This segment is a little less about the battery itself and more about the style of platform as a whole, but the battery is a defining hallmark.

Without any bodywork, an EV skateboard looks, well, like a skateboard. André the Giant’s Tech Deck, if you will. This simplicity allows for unrivaled modularity, enabling automakers to take a single platform and mold it into anything they want, from sports cars to trucks and executive sedans, with relatively minimal modification to the groundwork. It’s some clever thinking plucked right out of a child’s imagination, just as old concept car designers dreamed it’d be.

For its blank-canvas design, skateboard platforms have become the star choice for many premium EVs, including Rivian, Tesla, and Lucid. Excellent examples of the platform’s modularity include the GM’s Ultium, which spawned the Hummer EV, Silverado EV, and more, and Volkswagen’s Modular Electric Drive Matrix or MEB, father to the e-Tron crossover family.

Chest battery, a hybrid’s delight.

Far less common in current EVs, this battery is sometimes loosely referred to as a “chest” battery for its size and shape, and it’s made a fantastic case for itself in hybrids, plug-ins, and electrified variants of existing cars that’d otherwise be gas-only. Chest batteries are far smaller than skateboard platforms, meaning they often lack the capacity needed for interstate driving ranges, but they’re great at simply being “just enough” for just the right purpose.

Chest-style batteries aren’t modular in the sense that entire fleets can spawn from platforms centered on this battery. But they’re versatile for use in most hybrids and plug-ins, enabling the use of electric motors to greatly enhance performance and fuel economy without the sacrifice of being consigned solely to charging stations. Such vehicles include plug-in hybrids, capable of traveling a few dozen miles on electric power before firing those cylinders, or traditional hybrids that need no charging stations and can recuperate depleted energy through regenerative systems.

Many Toyota hybrids use such a battery tucked neatly beneath the rear seats or trunk. As an ex-Toyota service and parts employee, I’ve seen these packs swapped many times in aging hybrids – they even come packaged in actual chest chests that I somewhat recall being a bitch to open. The McLaren Artura and Ferrari SF90 supercars use one between the cabin and the engine bay, enabling hybrid operation and a dose of urban-friendly EV range. The F-150 PowerBoost also has a teeny-tiny chest battery saddled beneath the rear half of the cabin between the frame rails.

Whatever the hell old EV engineers were smoking.

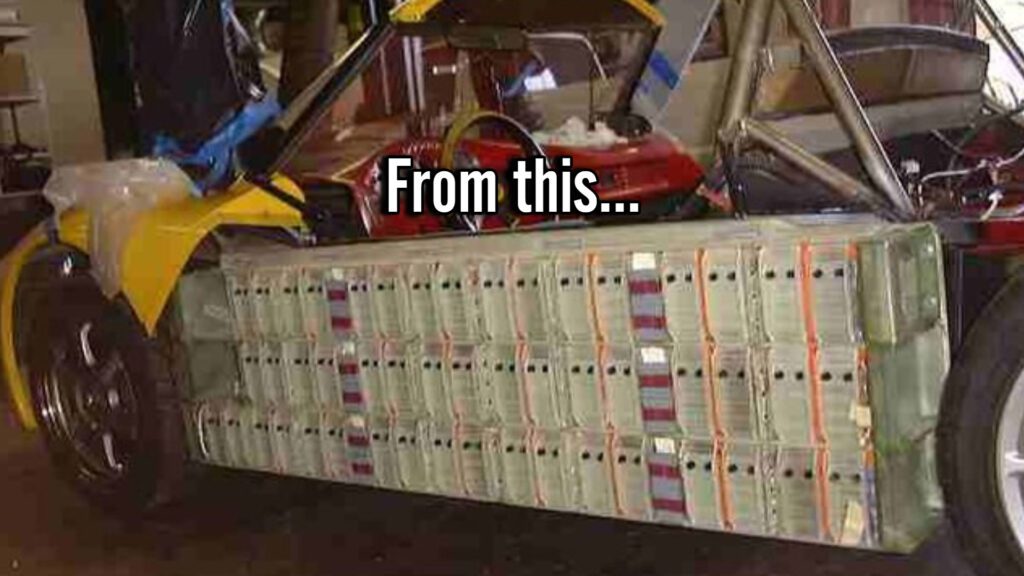

Rewind a couple of decades or so. Automakers and infantile startups were drafting ideas and whipping up concepts of what the cars of the future would be powered by. But of course, such fresh and unproven technology would have to be built to a budget using existing technology. So what does one do when needing batteries to motivate an entire car? Simple.

You wire a whole crap ton of them together. Bam! Where’s my electrical engineering degree?

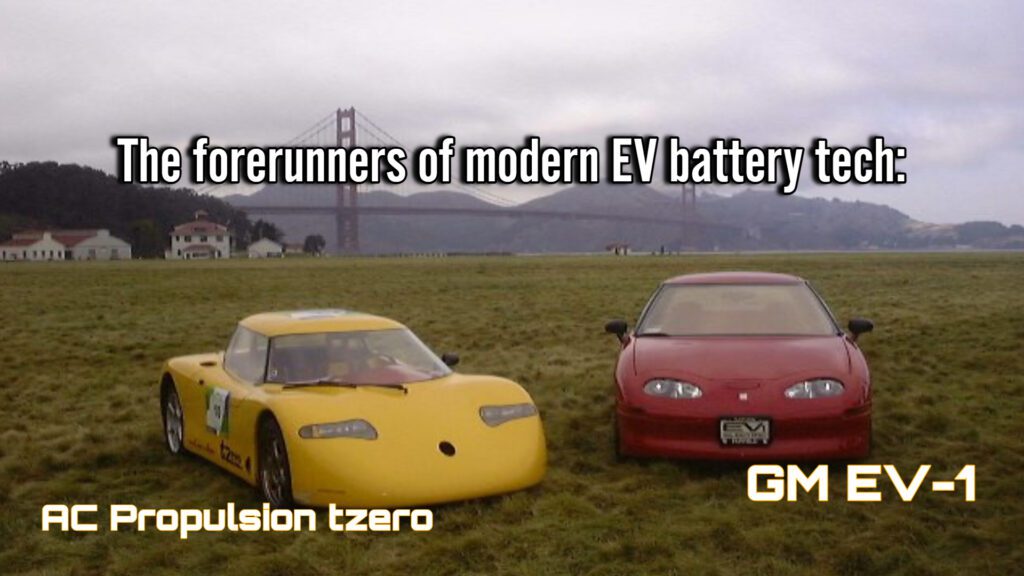

Seriously. You can probably find some ancient concept car set up this way and sitting pretty at automotive museums, like the AC Propulsion tzero prototype that laid the groundwork for the first Tesla Roadster. As you wire them in a series, their voltage and energy reserves stack, allowing for greater performance and range and increasing with every additional battery. If this sounds familiar, it’s because every wealthy retiree in the Florida Keys drives a golf cart with a power source like this.

EV battery composition

Ah, so that’s how they’re structured. But what exactly is in an EV battery? Are they any different in composition than the AAs in my Xbox controller? Not really, or at least if that’s if we’re talking about the more tried-and-true ways to concoct a box-o-electricity. Ways to formulate an EV battery often include the following recipes.

Lead acid

As the name implies, lead-acid batteries use trusty old lead as their electrode material. It’s more ancient than the first modern EVs. Hell, it’s more ancient than the Benz Paten-Motorwagen. And they kind of suck compared to everything else.

Lead-acid batteries are no bueno in the modern day, yielding the crappiest energy density of all the batteries to be fielded by modern EVs. But that’s to be expected with the march of time and technology. Lead acid was the move back then, as nickel-metal hydride tech for cars was in its infancy, and lead-acid was already plentiful. Automotive dinosaurs like the GM EV-1 and AC Propulsion tzero would don dozens of lead-acid batteries linked together to form relatively rudimentary battery packs that were hailed as wildly ingenious then.

In fairness, it was. And it worked, didn’t it?

Proven, common, and inexpensive, this composition saw widespread use as accessory batteries. Despite their low power density, their high surge currents are useful for starter motors and other car accessories. But as the formula for traction batteries, their inefficiency, relatively poor cold weather performance, and weight have seen them fall out of favor, not to mention that nasty corrosive stuff that can leak out when they degrade.

Nickel-metal hydride

Nickel-metal hydride batteries replace lead cathodes with ones of nickel oxide hydroxide, while the anodes are constructed of a hydrogen-absorbing alloy.

Quickly usurping the mantle from lead-acid, nickel-metal batteries promptly became the superior species for EVs and hybrids and is still in use today for many low-cost electrified vehicles. Although the cost-effectiveness of lead acid keeps them favorable for 12-volt accessory batteries, nickel-metal has earned its place in affordable EVs and many hybrids for its improved power density.

Later revisions of EV-1s and tzeros switched to nickel-metal, resulting in greater range and performance. And deep into the 2000s, hybrids were almost exclusively rocking chest batteries full of the stuff. Seems brilliant! Or at least it was until its next of kin came and took the mantle as nickel-metal did to lead-acid.

Lithium-ion

Welcome to the present, where lithium-ion reigns supreme, and all shall gawk at its perfection. Well, near perfection. Lithium-ion represents the current peak of battery technology, composed of a metal oxide cathode, a graphite anode, and an electrolyte solution of lithium salt and organic solvent. Lithium-ion doesn’t refer to one singular formula but rather an entire family of lithium-based recipes, which may include other metals such as cobalt or manganese.

Seemingly a no-brainer for current EVs and upscale hybrids, lithium-ion batteries yield significantly higher power density while also being able to be constructed smaller and lighter. These advantages mean you can do far more with much less. Bonus points for having lower self-discharge rates and little-to-no memory effect, the phenomenon where cells would gradually lose maximum capacity after being fully charged but only partially discharged. It’s not ideal in EVs, where one may plug in after a few dozen miles of commuting, but it’s almost entirely a non-issue with lithium. The list goes on.

Expectedly, most, if not all, deluxe EVs and high-trim hybrids use lithium-ion battery packs for farther range, performance, cold weather resistance, and efficiency, albeit at a price premium. But despite the financial hurdles, the increased normalcy of such batteries has seen its influence spread beyond mere Teslas, making new homes in common platforms such as the current-generation Toyota Prius, F-150 PowerBoost, Chevrolet Bolt, and more.

Solid-state

Alas, one final frontier exists for EVs. The elusive tech that is solid-state batteries stands as the next barrier to tear down. The idea itself isn’t actually all that new, but frequent drawbacks and the rise of comparatively inexpensive battery compositions stagnated its development in large-scale applications for nearly two centuries. But what makes it so special?

Solid-state batteries earn their name by literally being solid. Solid electrodes. Solid electrolyte. Composition ranges greatly, with existing small-scale examples using a variety of oxides, sulfides, and polymers. However, EVs will use lithium-based materials for the electrodes and electrolytes. Such composition is highly desirable for its immense power density than even today’s lithium-ion. Its construction is also safer, at least in theory, as solid-state batteries don’t necessitate solvent or acid electrolytes, which can be flammable in the heat of rapid charging or leak out of cells if the battery degrades. There are also the prospects of improved charge times and significantly lengthened driving ranges.

As to why it hasn’t yet taken off, automakers are still deciphering how to properly integrate solid-state batteries into cars with minimal compromise, as detailed in this Electrek interview with ION Storage Systems founder, Dr. Greg Hitz. While powerful and safer, solid-state batteries are unproven in their performance and incredibly expensive to manufacture. There are also concerns about inclement weather performance and the possibility of electrical shorts.

The challenges with solid-state batteries nearly match the industry-changing benefits offered. It’s confusing stuff shrouded in theories and speculation, and most automakers don’t anticipate it arriving in the mainstream for some time. Nissan and Toyota are perhaps the most eager and enthusiastic, keen on rolling out their production solid-state batteries as early as 2028.

The struggles and controversies behind EV batteries

Ah, the moment the haters have been waiting for and the evangelists have been dreading. But we can’t discuss EVs and hybrid batteries without discussing the horrid blemishes on their resume. As beneficial and game-changing batteries have become in the automotive world, they’re not without heaps of controversy, many too large to brush under the rug.

Flame on!

First responders can neutralize gasoline fires relatively easily. Battery fires, not so much.

Lithium batteries can create their own oxygen, negating tools such as fire blankets as they can fuel themselves, burning a thousand degrees hotter than a similar gas-fueled car fire. And to further fan the literal flames, it’s not like preventing a battery fire is as easy as not lighting those cancer sticks at the gas pumps.

The root causes of battery fires can be things completely out of your control and something neither you nor the OEMs can pick up on until it’s too late. Shoddy quality control within cells or cooling system leaks can cause catastrophic shorts, while malfunctioning or improper charging systems can overburden batteries, generating enough heat from excess current to ignite. Granted, layers of built-in failsafes keep these instances incredibly rare despite their glaring headline coverage, but one might never escape these thoughts lingering for now.

Many fire departments have admitted to being forced to adapt to the new threat of lithium fires, often resorting to using insane excesses of water or simply allowing the flame to wither out at the expense of the chemical fumes emitted. But it’s not just pollutants from a rare disaster that should worry the eco-minded.

Greta’s next boss battle

Yes, we can argue that merely driving an electric car is leaps and bounds cleaner than a gas car that burns hydrocarbons and dumps its combustion by-product into the air like the inconsiderate, woefully inefficient twit it is. In the sense that EVs can silently waft down the road emissions-free, call them Mr. Clean. But that’s not accounting for pretty much everything else under the burning sun that goes into a battery before the first owner ever puts it in Drive.

The shipping needed to transport materials overseas produces copious amounts of greenhouse gasses. Oh, and that comes after the drought-ending quantities of water and extensive labor required to pluck those materials right out of the ground, which will only increase with the development of more demanding solid-state batteries. When the battery has made it into the floor of a Tesla or the ass-end of a Prius, the environmental impact could take years of EV-only commuting to balance out.

You then must ask where the power comes from to charge your batteries. In regions relying heavily on methods such as nuclear or hydroelectricity, you have a best-case scenario with minimal impact versus charging in places that rely more on coal. However, some debate the validity of this notion under the guise that it matters little, as an EV charged on a coal grid will still be less impactful than a gas car existing in the same area. But such an argument fails to account for how every little bit demands more capacity from a grid, which can always be overwhelmed at any moment.

Essentially, the environmental impact is less about the cars themselves and more about their batteries’ side effects on the world, as the New York Times details. EVs and hybrids are indeed cleaner to drive but more polluting to produce, and the eco-friendliness of their charging widdles down to where the cars call home.

One refiner to rule them all

Although far less mentioned, another eyebrow-raiser is the heavy reliance on China as the main refiner and manufacturer of batteries. Nothing wrong with a country upping its game! Right? Except when governed by a highly controversial party frequently accused of imperialism and aggression against its neighbors, resulting in ceaseless tensions. One may also ponder the economic opportunities countries leave on the table by not refining materials themselves. Some countries are now projected to ramp up their participation in the coming years, cutting back on China’s near-monopoly while bolstering their own work forces.

But man, you just can’t fully shake off the idea of a country nearly controlling an entire aspect of the supply chain. I know this is a far-fetched, worst-case scenario, and perhaps I’m the cynical one just thinking about it, but I can only imagine what could become of the EV market if the world’s superpowers decide to reenact the plot of Battlefield 4.

Oh, pfft. That’s just a video game. They would never. Not when there are BYDs and Polestars that need to be built. Right?

Let’s wrap this up, I’m tired.

Recap for all our fine readers who stayed with us to the end!

Batteries, sometimes called traction batteries in fully-electric vehicles, are the literal source of power and performance in cars, no different to the AAs in your game controller or the daisy chain of 12-volts in your crazy neighbor’s bastardized home-brewed go-kart. The capacity of which we measure in kilowatt-hours. These metallic blocks of chemistry are constructed with a positive cathode to accept electrons, a negative anode to expel electrons into the circuit, and an electrolyte separating them through which ions may flow.

Battery packs come in various shapes, from Flat Stanley skateboards for unmatched versatility and energy storage in full EV platforms, to the loosely-defined chest batteries popular in plug-ins and hybrids. In the olden days, retro EVs (can’t believe that’s kind of a thing we can say now) would wire up bundles of lead-acid or nickel-metal batteries together into makeshift battery packs, no different from a golf cart.

Lead-acid and later nickel-metal were the go-to choices for battery composition, but nowadays, lithium-ion dominates for its improved power density and resiliency over all prior iterations. Today, automakers strive to conquer the next big leap for EV-kind, solid-state batteries, which theoretically promise even greater power density while being made safer and lighter.

And so the march of progress carries forward for electric cars, but hopefully, we have a greater understanding of the boxes of electrolytes stuffed into each one. Will they overcome their tainted reputation as new technologies suffer one hiccup after another? The optimist in me says that of course they will, but such advancement will never come without due trials. We can only wait and see how this malleable and evolving industry changes with the tides to overcome its tallest hurdles yet.