Over the past few weeks in Los Angeles, Elon Musk’s long-anticipated Tesla Cybertruck fever dream finally became an objectively verifiable reality. And not just on popular car-spotting Instagram posts, either. In early December, I actually witnessed a Cybertruck driving down the Pacific Coast Highway one morning. Then, a few days later, I cruised by one stuck in traffic on the 405. And unless someone got a quick wrap job done, I can also confirm that these first two sightings were, in fact, different Cybertrucks: one finished in that famous brushed stainless and the other in matte black.

Then, a few days later, the Petersen Automotive Museum invited select media for the debut of a new Cybertruck exhibit in the entry hall, complete with an exoskeleton sitting out in the open, as well as the truck that got shot by a Tommy Gun, and even a quick look at the original prototype downstairs in the museum’s Vault. Tesla designer Franz von Holzhausen actually owns the production Cybertruck on display bearing VIN #002—almost certainly the matte black one I saw on the 405—and even volunteered as tribute to answer questions from an almost certainly skeptical crowd.

But Musk and von Holzhausen are very busy people trying to change the world (maybe worlds if the Mars plan works out), so I felt absolutely zero surprise when I received a last-minute text bumping up the schedule. Then, when I arrived at the Petersen early, the poor PR pros on hand let me know that von Holzhausen never showed up. Interviews with lowly automotive journalists might not cut the mustard at Tesla, as it turns out, setting off a little warning bell dinging in my mind before I turned for a closer look at the angular hulking masses of metal making up the exhibit.

I wanted to pester von Holzhausen about why the production version shrank by a few percentage points, how the design iteration process began originally, and whether he also believed Tesla dug its own grave with the Cybertruck, as Musk admitted earlier this year. Instead, without a need to keep my game face (or audio recording) switched on, I spent the next hour-plus getting up close and personal with one of the strangest, most perplexing vehicles ever built.

First impressions of the angular Cybertruck

First off, outside on the Petersen parking garage’s first floor, I took a quick pic of a guy taking a pic of a Tesla Semi—full Christopher Nolan Inception soundtrack playing in my head, of course. In contrast to the Cybertruck, the Semi builds on von Holzhausen’s formerly smooth and aerodynamically efficient designs for the Models S, 3, X, and Y (and, supposedly, the forthcoming Roadster, but more on that later).

Not so much for the Cybertruck, an undeniable exercise in angular excess that attracted even more attention inside the Petersen’s entry hall. The black wrap and black exoskeleton only accentuated the presence of a bulky, boxy shape. The overall size surprised me, too, possibly attributable to the differences between seeing Cybertrucks out and about surrounded by other large cars as I rolled by on motorcycles.

Riding motorcycles in LA traffic is sketchy enough without stopping to rubberneck a controversial new electric pickup truck, so those early impressions only piqued my interest in taking a closer look at the Petersen. And the first thoughts to flit through my bedraggled pre-holiday mind ran the gamut from “gross!” to “gargantuan” because the angular peak sat higher than expected, even with the adjustable air suspension at its normal ride height. The cab looked bigger than in my mind’s eye, and the bed looked smaller. I began to wish I’d brought a tape measure.

Trying to get a better bearing on the actual adjustability of that air suspension system, I ducked into the wheel arch—if we can call it that since it’s squared off. The design somewhat resembled the finger knuckle A-arm of my old Type 955 Porsche Cayenne, except that where Porsche overengineered the Cayenne’s suspension, Tesla appears to have stamped the Cybertruck’s upper A-arm out of sheet metal. Not ideal for an electric truck that weighs north of 6,600 pounds, I thought. And in fact, von Holzhausen’s truck qualifies as the top-spec “Cyberbeast” (because, of course), so it should weigh closer to 3,800 pounds thanks to three electric motors.

Would the rest of the so-called “exoskeleton” continue that beefy theme? Well, in reality, Tesla calls the cage on display a “Body-in-white,” and the exoskeleton itself is made up of the body side panels that connect the front and rear structures, while the roof and rear wall connect the left and right sides. Obviously, we’ve come a long way from the by-now “traditional” skateboard battery layout. But the purpose here, other than general aspirations of badassery, actually involves reducing the number of parts required in what Tesla now calls a “Gigacasting” (because, again, of course).

In all honesty, the body-in-white impressed me more than the actual stainless steel exterior (albeit wrapped) of the finished product. But here, engineers probably received more control over the process rather than being forced to bring Musk’s vision of a slab-everything body to life. Tesla obviously needs to hit all the rigidity targets, accurate mounting points for subassemblies, and crash structure capabilities required by rules and regulations in order to bring the truck to market. Right?

Easy fodder for the critics (a.k.a. me)

Meanwhile, the visible flat panels of the finished truck do absolutely nothing to hide flaws. Even subtle curves or flowing lines on a normal—read: boring—car can help move eyeballs along without drawing awareness to peculiar or mismatched details. Flat planes make mistakes stand out, so Musk’s vision only made the production of Cybertrucks all that much more of a challenge (even beyond the sheer engineering requirements of cranking out an electric pickup with the aerodynamics of a brick).

To that end, the slightly rounded front panel might look the best, while the flat sides, angled inward up top with a flat windscreen that transitions to a roof, all seem somewhat cockeyed from almost every perspective. Is my mind playing tricks on me? Again, should have brought the tape measure. And maybe an eight-foot level to check those straight lines.

No straight line on the whole Cybertruck looks more egregious than the enormous combined hood and front windshield and its single wiper arm. Approximately 48 inches long, based on measurements compared to my wingspan, the arm pivots only from the driver’s side and will almost certainly struggle to keep the passenger’s side of the windshield clear. And will owners need to source wiper blades for semi trucks or road graders to fit? The blade almost reminds me of an early-2000s Mercedes-Benz CLK, but that wiper arm swung from the center with a strange hump in the pivot point to help cover more of the rectangular windshield (still not nearly as rectangular as the Cybertruck’s, though).

Then I glanced down through the windshield and noticed tiny openings at the base of the expansive, flat dash. Maybe for speakers, defroster vents, or both, these little openings looked entirely insufficient for either purpose. And I thought my mom’s second-gen Toyota Prius had a long dash—then again, maybe the low, raked windshield angle requires less air to prevent steaming up. On the other hand, that long dash reveals a major surprise about the Cybertruck that runs almost entirely counter to most other EV designs: Namely, the interior of such a large vehicle doesn’t even feel very spacious. The sharp edges and isolated lines of such a stark profile simply don’t allow for the kind of efficient packaging that made the Model S, 3, X, and Y so revolutionary when they each debuted.

Dino guts burnt to produce the plasticine era

Meanwhile, out in the front, that full-width plastic light bar sits below expansive panel gaps leading down from the windshield along the frunk hood. And below those gaps, through which I could probably sneak an HB #2 pencil, the plasticine fender flares around plastic and rubber wheel covers, simply put, look nearer to a child’s toy than a production pickup. Carved tires, a la most bold concept cars? Maybe on the original Cybertruck, but also a major surprise on von Holzhausen’s personal daily driver. Non-branded other than “Goodyear” and “Load Range D,” the tires themselves measure 285 millimeters in width at all four corners, though, as a recent scandalous video showed, perhaps lack the true kind of all-terrain or mud-terrain compound that such aggressive blocks and sipes might more regularly indicate.

The irony of using dinosaur guts to produce the plastic on an electric car entirely notwithstanding, the theme continues in the truck bed, too. There, a Petersen rep helpfully pushed the rubber buttons on the left side to roll up the shuttered bed cover and drop the tailgate—the latter worked but required a bit of a helping hand from me, too. (That rolling shutter, by the way, almost entirely kills any semblance of rear visibility.) But more importantly, because the buttons live out in the elements, they are made out of another plasticky-rubberized material reminiscent of jet ski controls or, somewhat hilariously, the Polaris Slingshot’s infotainment buttons.

In the rear bed, a light strip of similar material to the front brightens up all the black plastic on von Holzhausen’s truck. A real outlet in the bed reportedly powers 120-volt appliances, though I left my espresso machine at home, so I cannot confirm whether it functions—I see no reason why not, but here we are looking at a Cybertruck, after all. The thick bed walls funnel back towards the squared rear bumper, huge panel gaps continuing throughout. Of course, seals below the surface and a watertight battery pack for the skateboard might help, but the thought of this vehicle being able to drive as a boat across rivers and calm seas, as Musk claimed, seems unlikely.

And that’s not to mention the sharp edges at the end of each gap, especially noticeable up front with the frunk hood lifted. Not only will such sharp edges—made of stainless steel thick enough to inspire machine gun testing, remember—undoubtedly wreak havoc on any other cars in the case of accidents, but imagine a child jumping out of the frunk bench seat and hitting their head on the corner. Ouch!

Spartan to the point Of austerity

The questionable angularity continues on the Cybertruck’s interior, where if you thought the S3XY were Spartan, guess again. The steering wheel even gets a squared-off treatment, not quite a yoke but nearer to a racecar design (or a C8 Corvette but wider). As on the Model 3 and Model Y, the Cybertruck’s massive single touchscreen sits horizontally, as is the trend with Tesla, including the recently-revised Model S that now sports the same style of touchscreen. However, the dash also seems to lack climate control vents, too, unless there are tiny openings on the dash to do the trick, like in Model 3s. Controls on the steering wheel seem a step beyond the strict rollerballs and stalks of previous Teslas, but just about everything still requires diving into text-heavy menus on the main touchscreen, including apps, music, and suspension settings.

Selecting different ride heights elicits a noticeable increase or decrease in the wheel arch clearances, though the process of rising and lowering takes about as long as my 2006 Cayenne while the air compressor noticeably charges up pressures. Other options on the touchscreen include playing with the LED mood lighting, which von Holzhausen’s Cybertruck perhaps had set to a karaoke bar theme. I never counted the cupholders since I’m apparently the world’s worst automotive journalist (I blame the distraction factor of that huge dash, large enough to house a Winston Churchill war game).

Flat plastic door panels, flat plastic window switches, flat plastic on the center console, flat metal pedals, and then “Cybertruck” script welded into the foot sill—everything seems utilitarian to the point of no return. Will the remaining customer base who placed early pre-orders and now faces a price tag about half again as high as Musk promised to appreciate the cheaping out? Or do the diehards stick with their deposits and not care? Maybe they even love the austerity? Even the new car smell, still present despite von Holzhausen’s daily driving, smelled plasticky to the point of nearly Airstream-level formaldehyde. And smells are probably even more important in non-internal-combustion cars, believe it or not!

Machine gun testing, because of course

At least we know the Cybertruck truly can take a beating, if not a bowling ball, to the window. The next truck I wandered over to proved as much, riddled with dents and a few small metal tears after being shot with a series of 9mm and .45 caliber bullets. I brushed my hand up against some of the markings and can confirm that none appeared to pierce the metal entirely. Not bad, though, as a friend later suggested, some malcontents may relish the invitation to open fire on a famously bulletproof truck.

This early Cybertruck also gave me a chance to compare some of the differences that always emerge as concept cars progress through development on the way to production. Different fender flares and bumper designs stood out, and I started to wonder whether the design looked better in a matte wrap or exposed stainless. At the very least, wrapping flat stainless probably requires less effort than curved body panels. Or does it? Does it prevent any wrinkles and air bubbles? Maybe a wrap shop with experience working on DeLoreans can get the job done.

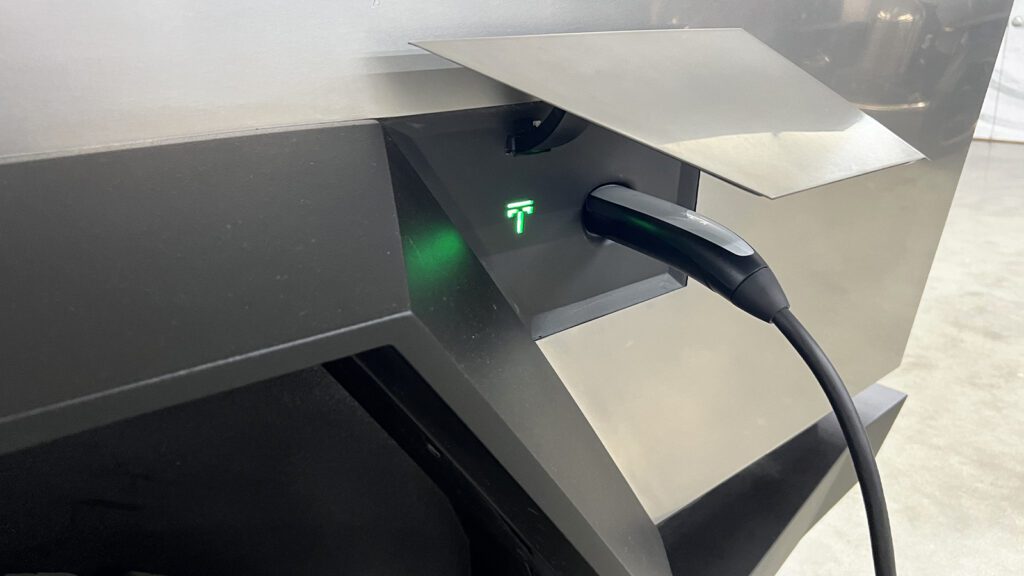

To wrap up the visit—pun fully intended—I headed down into the Petersen’s Vault, where the original Cybertruck concept sat charging. Again, the design differences stood out quickly. I spotted an earlier charge port, a cleaner rear bumper, and then a real steering yoke on the interior. Three semi-bucket bench seats made up the front row here, rather than the production version’s center console—the slight shrinkage in overall size might have made a third seat too narrow. If only von Holzhausen had shown up to confirm such speculation.

The concept truck also featured an even more radically squared-off dash design, so my skull naturally winced again at the thought of passenger impacts in the case of an accident. And better lenses on the light bar up front also stood out, even if a ton of fingerprints on the stainless steel distracted me once more. Keeping the raw metal clean looks like a nightmare task, so maybe the wrap is the way to go after all.

A sharply angled misdirection

Once I left the Cybertrucks and the Petersen behind, my mind kept wandering. At the very least, nobody can say Tesla built a radical concept car into a production vehicle without provoking serious thought about the state of the automotive industry. Bold and aggressive, the design sparks off a new stylistic generation for Tesla—but that’s exactly what the formerly S3XY Models need more than anything, and what buyers need more than an electric pickup truck that borders on gimmick status.

In a surprising moment of self-reflection, Musk all but admitted that perhaps the Cybertruck went a step too far. Not that such a startling truth prevented him from pushing forward into production. We’re far too far into billionaire celebrity-dom to admit certain levels of error or hand the naysayers any kind of victory. And everyone who’s an automotive nerd remembers a certain John DeLorean’s similar drug-fueled stainless-steel fiasco.

The fact that Tesla still plans to build the Cybertruck at all represents keeping a promise of sorts, which I suppose is a good thing. And something I always have to keep in mind while critiquing any running, driving car is that actually building a running, driving a car requires a miraculous combination of hard work and a fair amount of luck. But as the Cybertruck finally emerges from delay after delay, the end result still seems like something of a misdirection for the company’s efforts and resources. How about dedicating that work and luck to the cars more people will actually drive? What happened to the Roadster and promises of 600-plus miles of range?

Meanwhile, Tesla also desperately needs to direct more time and effort into parts and service for cars already on the road while continuing to press forward on the infrastructure change that Musk’s electric revolution requires here on Earth. Yes, Tesla is an automobile manufacturer. But the grandiose vision almost centers more around energy solutions than the cars themselves. And in the Cybertruck, all that energy focuses in the wrong direction.